Passenger Vessels for the World's Most Demanding Operators

Bringing Cutting-Edge Capability to Passenger Vessel Markets

Industry Leaders in Serialized Production

A Proven Track Record

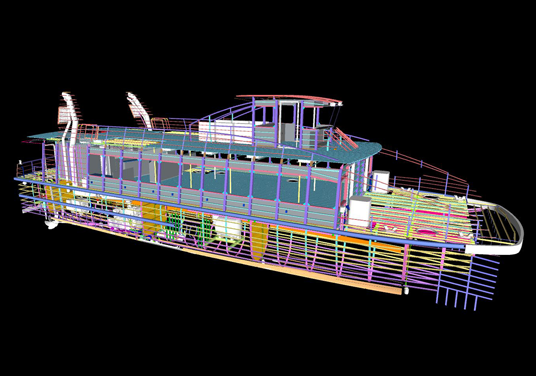

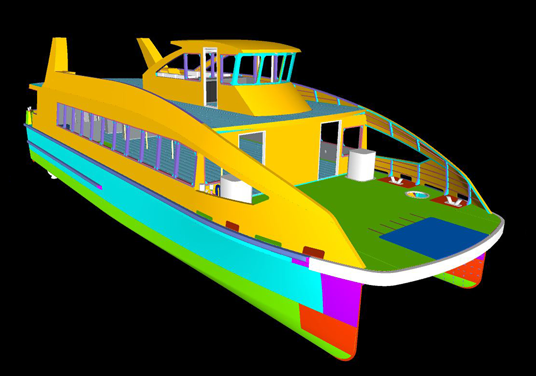

Formidable Engineering Strength

Design Firm Partnerships

Franklin Shipyard

Metal Shark Ferry Builds: NYC Ferry

In July 2016, Metal Shark was selected by HNY Ferry Fleet, LLC (a Hornblower company) to build 88′, Incat Crowther-designed, 150-passenger high-speed ferries for its new NYC Ferry Service. By incorporating the same serialized building processes honed on its military fleet builds, Metal Shark built and delivered the entire six-vessel order in record time. With less than ten months’ time from project start to the delivery of the first vessel, Metal Shark delivered all six ferries on or ahead of schedule, between April and June, 2017. NYC Ferry officially launched on May 1, 2017, with Metal Shark-built H 102 given the honors of ferrying the first load of customers on the new service’s inaugural revenue trip. Metal Shark is proud to count HNY Ferry Fleet, Hornblower, and NYC Ferry among its growing list of satisfied customers. In September 2017, a second order of NYC Ferries was announced. Production of 150-passenger and 350-passenger ferries for NYC Ferry is ongoing.

Metal Shark Ferry Builds: Potomac Riverboat Company

In January 2017, Metal Shark was selected by the Potomac Riverboat Company division of Entertainment Cruises to produce four 88’, high speed/low wake, 150-passenger aluminum catamarans for a new Washington DC transit service.The low-wake, low-wash USCG Subchapter T vessels were designed by BMT Designers and Planners and combine passenger comfort with fuel efficiency and low environmental impact. The new vessels provide commuters in the Washington DC metro region with service between Old Town Alexandria, Virginia; National Harbor, Maryland; and Georgetown and The Wharf in Washington DC. Potomac Riverboat Company parent Entertainment Cruises is the nation’s largest dining and sightseeing cruise company, with a fleet of 30 ships operating in over a dozen major U.S. cities. Construction on Potomac Taxi I and II commenced in March 2017, with both vessels finishing in September, approximately six months later. The remaining vessels, Potomac Taxi III and IV, were delivered in February and March 2018.

Metal Shark Ferry Builds: New Orleans RTA

In January 2017, Metal Shark was selected by the New Orleans Regional Transit Authority (RTA) to produce two 105-foot, 150-passenger, BMT-designed, aluminum high speed catamaran passenger ferries. These new vessels were designed to bring vastly improved passenger comfort and convenience, operating economy, safety, and environmental friendliness to New Orleans ferry routes, replacing the RTA’s two ferries built in 1977 and 1937. RTA 1 was completed and delivered to New Orleans in July of 2018, with RTA 2 completing in October. The USCG Subchapter “T” compliant ferries are powered by twin 715-horsepower Cat C-18 Tier 3 diesel engines, and as per RTA’s requirements the vessels feature a low wake/low wash, high efficiency hull design for reduced environmental impact. “In the past 18 months, we have delivered over fourteen 150-passenger and 350-passenger ferries to New York, Washington, DC, and now, New Orleans,” said Metal Shark CEO Chris Allard. “As a local Louisiana company, it has been an honor to build these modern, comfortable new vessels for the people of New Orleans and visitors from around the world.”

Excursion Vessels

Metal Shark Excursion Vessel Builds: Hubbard’s Marina

The “Flying Hub II” was a first-in-class foil assisted catamaran hull built by Metal Shark for Hubbard’s Marina, a Florida-based fishing and tour boat operator, and was delivered in August of 2017. Powered by twin 350-HP Yamaha four-stroke outboard engines, the vessel reaches speeds in excess of 35 knots. It is equipped with bench seating for 20+ passengers beneath a large canopy. The Flying Hub II was specifically configured for fishing excursions, nearshore and offshore, snorkeling trips, dolphin watching tours, and water taxi services. Learn more about the Flying Hub II.

Metal Shark Excursion Vessel Builds: Pure Florida

The second Jutson-designed foil-assisted catamaran excursion vessel built by Metal Shark, “Sea Flight”, was completed and delivered in August of 2019. Bench seating to accommodate up to 33 passengers is ideal for it’s intended use to offer a wide range of sightseeing, river and sunset cruises, Jet Ski tours and rentals, boat rentals, fishing trips and charters, eco-tours, educational field trips, and private family and corporate cruises. The vessel is powered by twin 440-horsepower Yanmar 6LY440 diesel engines coupled to Hamilton HJ292 water jets via ZF Marine 280-1 transmissions. Sea Flight cruises at speeds in excess of 30 knots and boasts a top speed of 40+ knots. Learn more about the Sea Flight.

Metal Shark is a proud member of the Passenger Vessel Association. You’ll find us at PVA events from coast to coast.

Metal Shark is a proud member of the Passenger Vessel Association. You’ll find us at PVA events from coast to coast.