Inland Commercial Vessels

Trusted by the Inland Sector’s Leading Operators.

Metal Shark serves Inland Waterways markets with custom-built, dependable steel vessels produced with the same military-honed project management systems, serialized production methods, and quality assurance programs perfected through the delivery of over 1,000 Metal Shark vessels now in service worldwide. Our shipyard in Bayou La Batre, Alabama is run by veteran industry professionals with decades of experience in the construction of complex, high quality steel vessels for some of the nation’s largest inland operators. Metal Shark Alabama supports inland operators with new vessel construction as well as a full range of Refit, Repair, and Conversion services and is capable of handling multiple simultaneous jobs. When it comes to inland transport, operators find we speak their language fluently.

Built Right. Delivered on Time. Specializing in Complex Builds.

Unmatched Engineering Resources

Metal Shark Alabama – Your Full Service Gulf Coast Shipyard

Metal Shark Alabama is a fully developed shipbuilding and repair complex in the Mobile Bay region, fronting a dredged deep water inlet. The facility boasts over 500′ of waterfront, five assembly buildings, a 660-ton Marine Travelift, multiple cranes, CNC plasma cutters, welders, and most importantly, a highly trained workforce specializing in the construction of inland steel vessels as well as their Refit, Repair, and Conversion. Metal Shark Alabama can capably handle vessels up to 300′ in length. The yard is located approximately 30 miles from Mobile, twelve miles south of Exit 10 on I-10. From the Gulf, the facility is ten miles north of Mile Marker 119.1E on the Intracoastal Waterway. Learn more about Metal Shark Alabama.

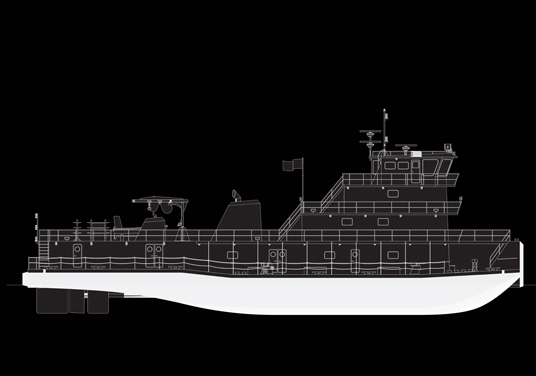

Recent Builds: Florida Marine Transporters, Inc. (FMT)

In late 2018, Metal Shark was awarded a contract to build three 120′ x 35′ inland towboats for Florida Marine Transporters, Inc. (FMT) of Mandeville, Louisiana. The four-decked, welded-steel, USCG Subchapter “M”-compliant towboats were designed by John W. Gilbert Associates, Inc. The vessels are powered by twin Cat 3512C marine diesel engines delivering 2,011 HP each at 1,600 RPM and turning 100” x 69” stainless steel propellers through Twin Disc model MGX5600DR reverse reduction gears with a 6.56:1 ratio. Sleeping accommodations and facilities have been provided for a nine-person crew. The first vessel was completed and delivered to the client in late April, 2020, and the contract was successfully concluded with the delivery of the third vessel in June, 2021 (press release here).

Metal Shark is a proud member of Waterways Council, Inc.

Metal Shark is a proud member of Waterways Council, Inc.