Metal Shark's Franklin Shipyard

In January 2014, Metal Shark acquired a 25-acre waterfront parcel in Franklin, Louisiana, and announced the construction of a new shipyard with direct access to the Gulf of Mexico. Starting from a blank slate, Metal Shark designed this new facility from the ground up to accommodate the latest serialized production methodologies, with flexibility and future expansion in mind. Operations at Franklin commenced in July 2014 in a new 60,000 square foot assembly building featuring four assembly bays equipped with overhead cranes. Additional amenities included protected deepwater berths, crane-in / crane-out launch capabilities, onsite offices for engineering and production management, and ample room for storage and staging. In April 2016, the yard was recognized with the first of several Small Shipyard Grants awarded by the United States Department of Transportation’s Maritime Administration (MARAD). In October 2016, Metal Shark installed a new 150’ x 80’ building for final assembly. A new 160-ton Marine Lift transporter arrived in early 2017 to facilitate the movement of boats around the yard and to water for launch. Expansions in 2018 included the construction of a fully enclosed 200′ x 80′ large vessel assembly building enabling the weather-independent construction of vessels up to 180’ in length, and a new three-story office building to house the yard’s facility managers, production supervisors, project managers, and in-house engineering staff. More recent improvements include the development of additional rigging areas to allow for the simultaneous construction of four additional large vessels.

In July 2016, Metal Shark was selected by HNY Ferry Fleet, LLC (a Hornblower company) to build 88′, Incat Crowther-designed, 150-passenger high-speed ferries for its new NYC Ferry Service. By incorporating the same serialized building processes honed on its military fleet builds, Metal Shark built and delivered the entire six-vessel order in record time. With less than ten months’ time from project start to the delivery of the first vessel, Metal Shark delivered all six ferries on or ahead of schedule, between April and June, 2017. NYC Ferry officially launched on May 1, 2017, with Metal Shark-built H 102 given the honors of ferrying the first load of customers on the new service’s inaugural revenue trip. In January 2017, Metal Shark was awarded a contract to build four 26-meter, 150-passenger ferries for Potomac Water Taxi. Between 2017 and 2020, Metal Shark Franklin built and delivered over 35 passenger vessels for various operators, including an astounding 22 150-passenger and 350-passenger vessels for the NYC Ferry service.

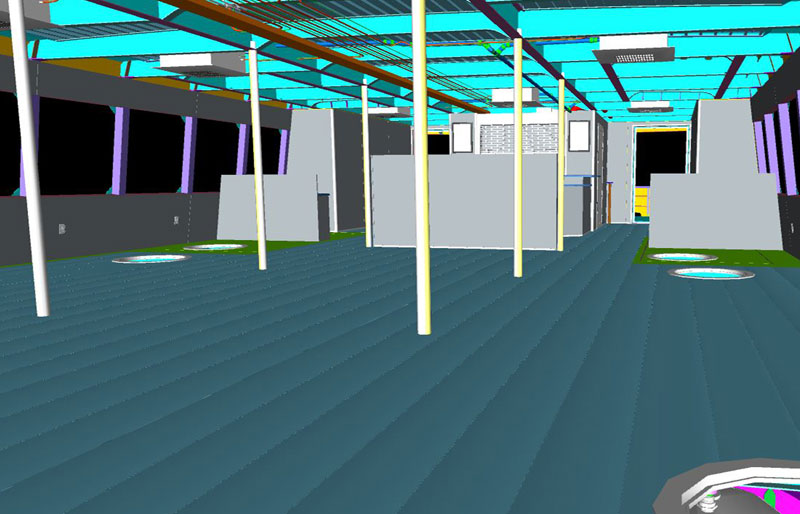

Metal Shark’s Franklin yard offers the unmatched benefits of an in-house engineering team composed of over 60 naval architects and marine engineers. Metal Shark leverages this formidable resource to create its own highly specialized and thoroughly engineered vessel designs and also to interface seamlessly with outside engineering firms to assure precision results. Metal Shark works with leading design firms including Incat Crowther, BMT Designers and Planners, BMT Nigel Gee, One2Three Designs, Marine Design, Jutson Design, Damen Shipyards and others to offer technologically advanced vessels that are custom-tailored to meet exacting customer requirements. Metal Shark goes above and beyond, utilizing extensive 3D modeling to allow the project to be realized in advance, greatly facilitating planning, resource allocation, and an exact interpretation of each vessel’s design for precision, quality results. Metal Shark backs up this engineering strength with the support of highly capable, industry veteran project managers who are tasked with keeping each project on time and on budget.

Committed to Health, Safety, Security, and the Environment

From the top down, members of the Metal Shark team work to assure a safe and secure environment for the benefit of its employees and the greater good of the communities the company calls home. Metal Shark’s safety record is a source of evident pride among team members. As proof of its commitment to excellence, Metal Shark has been recognized by the Shipbuilders Council of America (SCA), winning the SCA’s Award for Excellence in Safety for four consecutive years and counting. Click here to learn more.

Learn more about our Jeanerette Production Facility.